Product Name:2580/580-SERIES HIGH-SPEED TRANSMISSION LOGGING SYSTEM

|

Type:

|

HH-2580/580

|

|

producer:

|

Huanding Energy Services

|

|

Description:

|

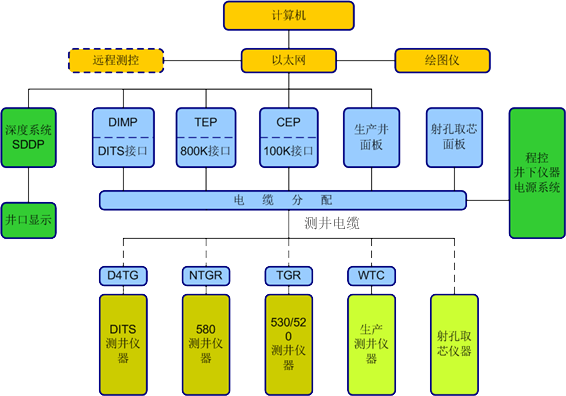

HH2580/580-series high speed transmission logging system is composed of three parts: HH2580 nets transmission logging surface system, standalone depth display panel, and 580-series logging tools.

|

FUNCTIONHARDWARE SYSTEMSOFTWARE SYSTEMSTANDALONE DEPTH DISPLAY PANEL, SDDP

HH2580 surface system is compatible with the following logging tools:

1. Connecting 530-series Downhole Tools

The communication

mode TCC (CTS) is retained, which is used for 530-series downhole tools

The conventional

530-series downhole tools are: stiff electrode (electrode array), CCL,

auxiliary measuring sub, telemetry/GR logging tool, spectrum natural GR logging

sonde, compensated neutron logging sonde, common electronic circuit section 1,

hydraulic pad-mounted device, MFS and LDS combined logging sonde, borehole

deviation logging sonde, common electronic circuit section 2, dual lateralog

logging sonde, high resolution acoustic logging sonde, X-Y caliper

(4-independent-arm caliper), dual induction logging sonde, etc.

Diplog Meter;

Repeated Formation

Tester, etc.

2. Connecting 580-series Logging Tools

The surface system communicates with the downhole tools by ADSL mode,

which matches 580-series logging tools. 580-series logging tools are: Stiff

Electrode (electrode array, SP). Digital CCL, Net-oriented Tool for Temperature

Tension Mud Resistivity, Net-oriented Telemetry and GR Sub, Net-oriented

Digitalized Four Arm independent Caliper, Multichannel GR Spectroscopy Tool,

Net-oriented Compensated Neutron Sonde, Net-oriented

nuclear electronic cartridge 1, Net-oriented Hydraulic Activation Sub, Density

Sonde And Micro-spherical Focused Sonde, Net-oriented Compensated Neutron

Sonde,Net-oriented

Resistivity and Borehole Deviation Electric Cartridge, Net-oriented Dual Laterolog Sonde, Net-oriented Digitalized Sonic Sub, etc

3. Connecting DITS-series Logging Tools

(optional, adopting HES software)

4. Connecting WTC-series Production Logging

Tools and Annular Production Logging Tools

5. Function of Perforating and Side Wall

Coring

1. Environment Condition

Environment Temp.:

0℃~+50℃

Storage Temp.: -20℃~+75℃

Relative

Humidity: <95%

no condensated water at the temperature of45℃

Vibration:

3D 3g

10~60Hz

Shock: 3D 10g 11ms

2. Composition

---Industrial

computer (double configured or a laptop optionally),

---530 interface

panel,

---580 interface

panel,

---Perforating

interface panel,

---DITS interface

panel,

---Electrode array

panel,

---Cable switchover

panel,

---Network exchanger

panel

---DCCP DC power supply

controller panel

---Sorenson DC power

supply panel

---Two ELGAR power

supply panels ( programmable controlled, 1250/2500 W),

---TPS panel (tool

power supply),

---Plotter (double),

monitor (double), UPS,

---Remote satellite

communication interface panel

3. Logging

Main Industrial Computer or Laptop

Industrial

Computer: P4 (2.8G) 80GHard Disk

512MMemory,

readable and writable CD-Rom driver

10/100Mself-adaptive network port.

Laptop: world known brand with qualified configuration

4. HH2580 Acquisition Interface

Embeded

Computer PC104: Main Frequency233M,

10/100Mnetwork port,

Working

Temp.:-25℃~+75℃

Acquisition

Channel:

Telemetry Channel: ≥800kb/s ADSL

5.192Kb/s

Manchester Code

Analog Channel: 23 channels,

dynamic range:0~+10V、16bitA/D converter

Programmable gain:

×1,×2,×4,×8,×16

Pulse Channel: 8 Channels

16-bit

counter Max counting frequence 1MHZ

Special Analog Signal Processing

Channel: 4 channels

Depth Signal Processing Channel: 2

Channels

Loadcell Channel: 2 Channels

D/A Output: 2 channels, 12 bits output

GPIB Communication Function: Real-time duplexing

data transmission with depth panel

5. DITS Acquisition Interface

Main

Computer: Main

Frequency133M,

10/100 MNet Ports,

Working Temp.-25℃~+75℃

Acquisition

Channel:

Telemetry:

DITS-series tools

Analog Channel: processing and digitalizing of spontaneous

potential (SP) signal;

RS485 (GPIB) Channel: Communicating with SDDP

6. Power Supply to Downhole Tools

Main AC Power Supply: 0~800V AC,1.2A

Auxiliary AC Power Supply: 0~800V AC,1.2A

Adjustable DC Power Supply: Max:

±600V DC,3.4A

7.Uninterrupted

Power Supply

220V, 50Hz AC

input, 1200VA

8. Structure

Two sets of rack: one tall, one short

One operation desk

9. System

Power Supply

~220±10%VAC

/50±2Hz

10. Reliability

Mean Time Between Failures≥

3000h

11. Maintainability

MTTR≤0.5h (Mean Time To Repair)

·It

is a newly compiled software version with up-to-date technology.

·Software

configuration includes 530 module, 580 module, production logging module,

perforation module, data processing module.

·Networked

software design,.

User can perform remote communication

mode from single user to multi-user.

·Modularization,.

Each tool has

it's own database, guarantee system the strong

expansibility.

·Back-stage

management.

The logging

software manages logging data through backstage database. Providing a convenient

way for multi-user to inquire and playback logging data.

·Mass

information store and diagnose.

Operator can

detect working status by various logging event recording, therefore, fault

locating and eliminating could be easier.

1. FUNCTION

It

has two sets of completely independent signal processing circuit system. When

operation software is on, one of them is used as the main system. The output of

the main one is used for logging acquisition and display, and the other is as

back up automatically. Its output can be monitored in real time in the logging software.

When the main one is considered malfunction, the back up one can be switched to

apply by software option

When

user starts up the tension/depth panel, the parameters last time configured are

applied automatically.

The tension/depth

can be displayed both at the position of winch operator and in logging

software, and the tension/depth parameters can be input at either side. No

matter which side they are input, the values of the other side will be

correspondingly changed. The two sets of tension/depth system parameters can be

input respectively by selecting it as the main system in the logging software.

Without initiation of

the surface system, the tension/depth system parameters can be set up by

tension/depth display panel. On starting of the surface system, the logging

software uses the tension/depth system parameters already set-up automatically.

12VDC battery is used for power supply

The

units of depth and tension value can be selected, that are: Meter/Feet; LB/kg.

Surface and downhole cable

tensions are needed to display at both the driller and winch operator.

Depth

alarm, speed alarm, tension alarm, etc.

The

hoist can stop automatically based on the setting shut off tension value.

Various types of

loadcell can be compatible with SDDP.

2 SPECIFICATIONS:

Working Environment

Working Temp.: -25℃-+85℃

Altitude: 5000m

Vibration: 20-500 Hz,

0.02g2/Hz

Working Power

Input Power: 12VDC

Input signals

Differential

signal of depth encorder : Amplitude

5V

Differential

signal of loadcell: DITS

tension signal;

loadcell made in China: 0-5VDC

GPIB

input signal from surface acquisition

Outputs

Power

supply of depth code wheel: +5VDC

Power

supply of loadcell: +12VDC

Power

supply of tension braking signal: +12VDC

GPIB

Communication

Communicate

with wellhead displayer : outputting and transmitting downhole tension signal

and depth signal to well head displayer.